AJR AUH-II Ultrasonic Hardness Tester

Working Theory

Ultrasonic contact impedance method (UCI) is a kind of dynamic indentation method for measuring indentation indirectly. A vibration rod with a specific indenter (such as a regular quadrangular diamond indenter) is excited to do longitudinal ultrasonic vibration, and the indenter is pressed into the surface of the test piece with a certain test force, and the longitudinal vibration of the vibration rod will be subject to impedance and the resonant frequency will change. Its variation is a function of the indentation surface area and the effective elastic modulus of the system, and the hardness value is obtained from the frequency change.

|

|

1 |

Spring |

5 |

Amplifier |

|

2 |

Vibrating Beam |

6 |

Receiver |

|

|

3 |

Indenter |

7 |

Emitter |

|

|

4 |

Test Piece |

|

|

Features

Ø Base on “GB/T 34205-2017 Metallic-materials-Hardness testing-Ultrasonic contact impedance method“, AUH-II ultrasonic hardness tester can be used for high precision detection of various metal materials.

Application

Ø Flange edges and gear roots, stamping parts, sheets, surface hardened teeth and gear grooves;

Ø Hardness measurement of shafts and pipes and containers;

Ø Hardness measurement of wheel and turbine rotor;

Ø Hardness measurement of bit edge;

Ø Hardness measurement of welded parts;

Ø Measure holes of a certain size, bumps with large radians and irregular planes;

Ø Hardness measurement of most ferrous metals, non-ferrous metals and their alloys;

Ø Material differentiation of metallic materials;

Ø Rapid inspection of multiple measurement parts in a large range of large workpieces.

Load Force

Application

98N

Welds, cast iron, cast aluminum, induction heating.

50N

Induction heating, case hardening, tools, Aluminum.

20N

Flange, gear, stamping

part, mould, crank axle,turbine rotor.

10N

Surface hardness, plasma nitriding, small complex formed parts, aluminum.

8N

Precision

parts, retarders and bearing rotation rings.

3N

Coating

(plating) layer, coating of low pressure cylinder, hardening layer.

1N

Thin layer,

polished surface.

Specification

|

Test Direction |

AUH-II supports 360° degree direction test. But Probe must be perpendicular to the tested work piece surface. |

|

Indenter |

136° Vickers Diamond Indenter. |

|

Hardness Scales |

HV, HB, HRB, HRC, HRA. |

|

Hardness Range |

HV: 10 - 1999; HB: 76 - 618; HRB: 41 - 105; HRC: 20.3 - 68; HRA: 60.7 - 85.6. |

|

Result Display |

HV + Hardness scale which is selected. |

|

Measureing Accuracy |

HV: ±4% HV; HRC: ±1.5 HRC; HB:±4% HB. |

|

Test Material |

Steel and cast steel, Cast aluminium, Copper. |

|

User Customized Materials |

3 kinds, with setup wizard. |

|

Display |

3.5 inch IPS digital color LCD, resolution ratio 480×320. |

|

Probe Identify |

Automatic recognition / Manual setting. |

|

Data Memory |

600 groups max. |

|

Battery |

3.7V Lithium battery. |

|

Working time |

>10 hours. |

|

Charging Port |

5V/1000mA. |

|

Communication Port |

USB2.0. |

|

Main Unit Dimension |

159×83×39mm. |

|

Probe Size |

Φ22×141mm. |

|

Main Unit Weight |

370g. |

|

Probe Weight |

210g. |

|

Operating Environment |

Temperature:-10℃~50℃; Humidity: 30%~80%R.H. |

|

|

Measurement uncertainty (Max) Erel % |

||||||

|

HV1 |

HV2 |

HV5 |

HV10 |

HV0.1 |

HV0.3 |

HV0.8 |

|

|

< 250HV |

4 |

4 |

4 |

4 |

5 |

5 |

4 |

|

250HV - 500HV |

4 |

4 |

4 |

4 |

6 |

6 |

4 |

|

500HV - 800HV |

5 |

4 |

4 |

4 |

7 |

7 |

5 |

|

> 800HV |

6 |

4 |

4 |

4 |

8 |

8 |

6 |

|

|

Relative Repeatability (Max) rrel % |

||||||

|

HV1 |

HV2 |

HV5 |

HV10 |

HV0.1 |

HV0.3 |

HV0.8 |

|

|

≤ 250HV |

8 |

5 |

5 |

5 |

8 |

8 |

9 |

|

> 250HV |

6 |

5 |

5 |

5 |

6 |

6 |

6 |

Manual Probe Specification

|

Manual Probe |

1kgf |

2kgf |

5kgf |

10kgf |

|

Accessory Type |

Optional |

Standard |

Optional |

Optional |

|

Test Force |

10N |

20N |

50N |

98N |

|

Diameter |

22mm |

22mm |

22mm |

22mm |

|

Length |

150mm |

150mm |

150mm |

150mm |

|

Resonant Rod Diameter |

3.1mm |

3.1mm |

3.1mm |

3.1mm |

|

Maximum Roughness of Test Surface |

Ra<3.2um |

Ra<5um |

Ra<10um |

Ra<10um |

|

Workpiece Min Weight |

0.3kg |

0.3kg |

0.3kg |

0.3kg |

|

Workpiece Min Thickness |

2mm |

2mm |

2mm |

2mm |

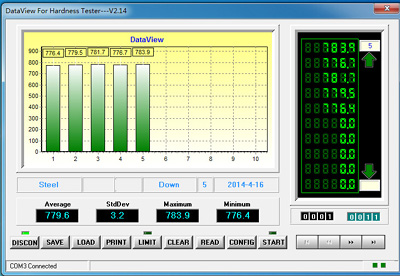

Data Software

Standard Accessories

|

No. |

Item |

Qty. |

|

1 |

AUH-II Main Unit |

1 |

|

2 |

2Kgf Manual Probe |

1 |

|

3 |

Probe Cable |

1 |

|

4 |

Block |

1 |

|

5 |

Charger |

1 |

|

6 |

Charging Cable |

1 |

|

7 |

Carry Case |

1 |

|

8 |

Warranty Card |

1 |

|

9 |

Quality Certificate |

1 |

|

10 |

Operation Manual |

1 |

|

11 |

Calibration Certificate |

1 |

Optional Support Ring Specification

|

Support Ring Name |

Plan Support Ring |

Cylinder Support Ring |

|

Application |

|

|

|

Test flat surface |

Test round surface of diameter 5-80mm |

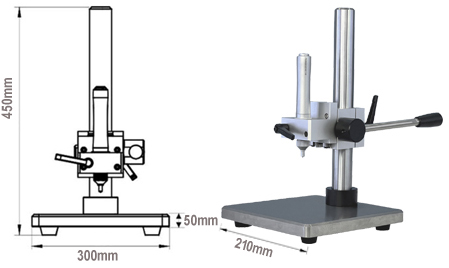

Optional Stand

|

Column |

Stainless Steel, Alloy |

|

Bottom |

Marble Material |

|

Packing Size |

24 x 53 x 30 cm |

|

Weight |

13kg |

Optional Block Specification

|

Hardness Range |

Uniformity |

Roughness |

Dimension |

|

(28~35) HRC |

±1.5 HRC |

Ra = 0.02 um |

Ø90 x 16mm |

|

(38~45) HRC |

±1.5 HRC |

Ra = 0.02 um |

Ø90 x 16mm |

|

(48~55) HRC |

±1.5 HRC |

Ra = 0.02 um |

Ø90 x 16mm |

|

(58~65) HRC |

±1.5 HRC |

Ra = 0.02 um |

Ø90 x 16mm |

|

(50~999) HV1 |

±3% HV |

Ra = 0.02 um |

Ø90 x 16mm |

|

(50~999) HV5 |

±3% HV |

Ra = 0.02 um |

Ø90 x 16mm |

Address: Room 1603, Unit 2, 1# High Building, B Area, Dong Liang She Village, Huining Town, Xindu District, Xingtai City, Hebei Province, China 054001.

Tel:+86-0319-2827816

Whatsapp / Mobile / Wechat: +8613393190604

Skype: vince-hu1

Email: sale@ajr-ndt.com

ajrtradeexport@hotmail.com

Web: www.ajr-ndt.com

Copyright © 2010-2026 AJR NDT CO., LTD All rights reserved